Ultrasonic Transducer for Ink Cutting" is applicable to cut ink off nozzle of the non-contact inkjet printer. Due to differences in industry terms, it’s commonly known as "resonators" in inkjet industry. For the ease of understanding, the following description adopts “resonator”.

Vibration Mechanism

Resonator is generally composed of a piezoelectric crystal and drive rod. The resonator generate high-frequency ultrasonic vibration (60 KHz and above) and a micro-displacement (stretching back and forth) of same high-frequency in the front-end by high-frequency electrical stimulus.

In the elastic medium, such as water or ink, this kind of medium will spread the ultrasonic vibration in column wave form. At this time, the medium vibrates in a sparse-dense alternating regulation. To the medium, the sparse point is pulling force (negative pressure) and the density point is pressure (positive pressure). It is 1/2 wavelength distance between the two points.

Cutting-off Ink Mechanism

The ink is pushed to the chamber by a pump and spray out from a few dozen microns hole (nozzle) in the front-end of the chamber. The injected ink is of a continuous flow line of fine ink.

Ultrasonic-off ink is realized through superimposing the high-frequency vibration wave generated by resonator before the ink line flow injected. The column wave of the ink line flow vibrates in a sparse-dense alternating regulation and generates negative and positive pressure wave. The injected ink is cut off at the negative pressure and shrinks into a ball at the positive pressure. Thus, the ink forms into equidistant and same size particles flow.

Inkjet Printer Mechanism

The formation mechanism of character coding is similar to that of CRT imaging. The ink-flow particles transform into a stream of charged particles by high-pressure polarization, flying through the detection area and the high-pressure electrode deflection zone and finally become a lattice falling onto the surface to be printed.

Because of the low power of resonator, this technique generally applies to small inkjet printers.

Classification of Applicable Inkjet Printers

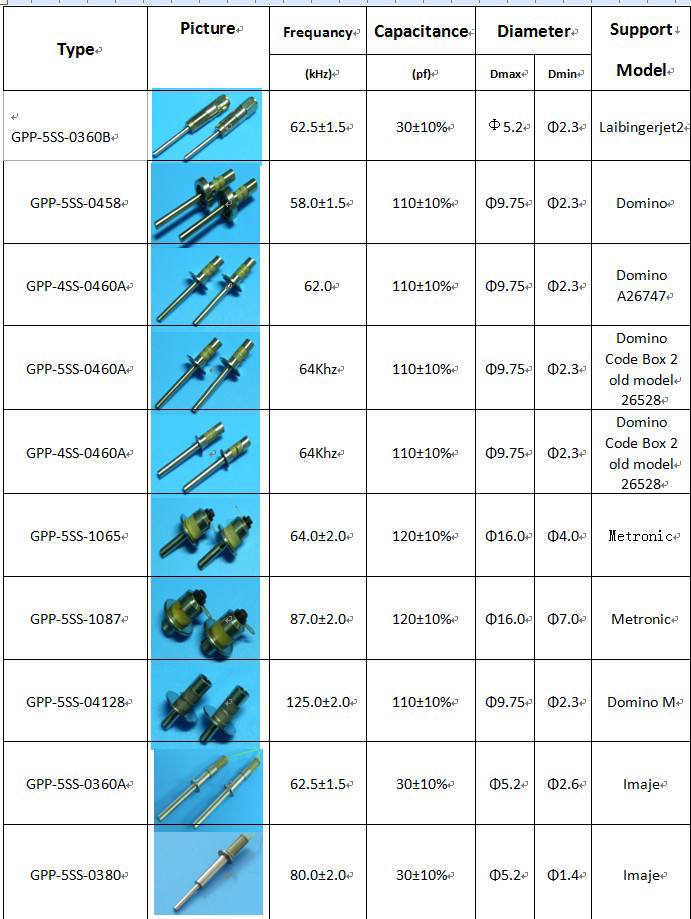

Our Company's products are mainly applicable to imported brands of printer and domestic printer. Specifically:

Imaje Series: 62.5K(model G), 80K(model M)and 125K(model P);

Domino Series: 58K (alcohol Ink), 64 KHz (model A) and 128K (model M);

Metronic series: 62.5k(same as Imaje G)、65Khz and 87Khz;

Laibinjet series:62.5k,69k;

Videojet (Willett): 55 KHz, 75 KHz and125Khz

Hitachi: 75K

Chinese type: 62.5 kHz and latest improved model: 75 KHz, 80 KHz, etc.