|

|

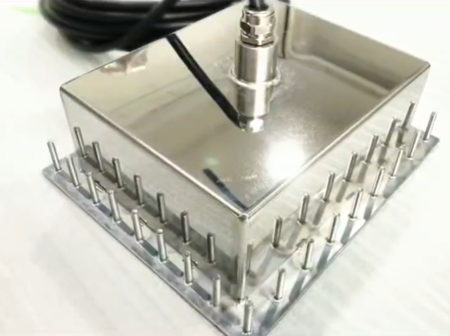

Ultrasonic megasonic cleaningUltrasonic megasonic cleaning As we all know, ultrasonic cleaning is a common efficient and fast physical cleaning method, the cleaning effect is significant and the operation is simple, reducing the possibility of secondary pollution due to the complex chemical cleaning process, and for complex devices can also achieve the purpose of cleaning, so it is widely used in various industrial, medical, civil and other fields. The core principle of ultrasonic cleaning is to use the cavitation effect of ultrasonic waves in the liquid to remove the stains on the surface of the object. What is the ultrasonic cavitation effect? Ultrasonic high-frequency mechanical vibration in the liquid will produce tiny bubbles, these tiny bubbles will expand rapidly, and then suddenly closed, in the closure will produce a powerful shock wave, this expansion, closure, vibration of the dynamic process is called ultrasonic "cavitation effect". "Cavitation effect" not only provides enough energy for the chemical and physical reactions in the cleaning process, but also the instantaneous high pressure generated constantly impacts the surface of the cleaning workpiece, and also makes the surface of the cleaned object and the foreign matter in the gap quickly stripped away. However, too strong ultrasonic cavitation will also cause certain damage to the surface of the object, such as in the cleaning of precision components such as semiconductor devices and optical precision parts, because there are some microstructures on the surface of the device, traditional ultrasonic cleaning will cause a certain degree of damage to the surface. At the same time, the higher the ultrasonic frequency, the smaller the bubbles, and the smaller the particle size of the removed impurity particles, that is, the higher the cleaning accuracy. The frequency of traditional ultrasonic cleaning transducers is between 20kHz-100kHz, and the cavitation effect in this frequency range is large, which will cause damage to precision components, and it is difficult to remove impurity particles below 1 micron. When the ultrasonic wave with a frequency higher than 400kHz propagates in the liquid, it can form a very thin acoustic boundary layer with a large velocity gradient near the surface of the cleaned part, and the impurity particles are shed from the surface of the device by the oscillation of the liquid megahertz frequency, and the micron and sub-micron impurity particles on the surface of the components can be cleaned to achieve ultra-precision cleaning process. In addition, the high-frequency ultrasonic cleaning process will not cause damage to the surface of the cleaned parts due to the extremely low cavitation effect, which can effectively solve the corrosion or damage caused by the cleaning of precision components. Therefore, the ultrasonic device that can emit megahertz level is widely used in the field of semiconductor manufacturing, and in addition to its cleaning effect, it can also play an important role in chemical mechanical polishing, development, degluing, metal stripping, etching and other key processes. The ultrasonic wave at the frequency of megahertz is often referred to as "megasound" in the industry, so the ultrasonic cleaning in this frequency range is also known as megasound cleaning.

|